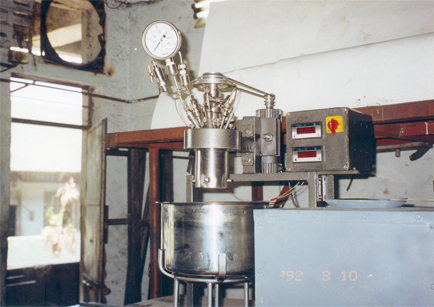

10 Litre Electrically Heated Pilot Reactor for Hydrogenenation

10 Litre Electrically Heated Pilot Reactor for Hydrogenenation Specification

- Phase

- Single Phase

- General Use

- Industrial

- Material

- Mild Steel

- Capacity

- 10 Ltr

- Control System

- Human Machine Interface

- Voltage

- 220 Volt (v)

- Feature

- High Efficiency

- Warranty

- 1 Year

10 Litre Electrically Heated Pilot Reactor for Hydrogenenation Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 5-7 Days

- Main Domestic Market

- All India

About 10 Litre Electrically Heated Pilot Reactor for Hydrogenenation

Competitive Advantages & Application Specifics

The 10 Litre Electrically Heated Pilot Reactor offers superb efficiency for hydrogenation in pilot-scale production. Used predominantly in industrial settings, it's highlighted by its user-friendly Human Machine Interface and robust mild steel build. Its competitive edge lies in reliable temperature control, adaptability in R&D, and ease of scale-up. Ideal for chemists, engineers, and process developers, this reactor thrives in research labs and small-batch manufacturing, delivering remarkable performance for various hydrogenation reactions.

Packaging, Supply, and Market Reach

Experience Quick Dispatch and secure Goods Transport with every order of the 10 Litre Electrically Heated Pilot Reactor. Packaging adheres to industrial safety standards, ensuring the unit reaches customers in prime condition. With a consistent supply rate, we efficiently serve bulk and individual orders nationwide. Our main domestic market extends across India, offering traders, manufacturers, and end-users reliable access to this high-quality reactor, with prompt and professional logistical support every step of the way.

FAQ's of 10 Litre Electrically Heated Pilot Reactor for Hydrogenenation:

Q: How does the 10 Litre Electrically Heated Pilot Reactor improve the hydrogenation process?

A: This reactor provides precise temperature control and rapid, even heating, resulting in more efficient hydrogenation reactions and higher product quality. The advanced Human Machine Interface allows operators to easily manage and adjust process parameters.Q: What are the main benefits of using this reactor in an industrial setting?

A: It offers superb operational efficiency, remarkable durability due to its mild steel construction, and versatile application for pilot and research-scale hydrogenation. Its automation and control system reduce manual intervention and improve safety.Q: When is the ideal time to use this reactor in your process workflow?

A: This reactor is ideal during pilot-scale developments and testing phases of hydrogenation projects, before scaling up to larger production. It is also well-suited for batch productions in R&D environments.Q: Where can this pilot reactor be installed?

A: The unit can be installed in research labs, pilot plants, and industrial facilities focused on chemical processing, especially where high-quality hydrogenation pilot runs are conducted.Q: What is the packaging and delivery process for the reactor?

A: Each reactor is packaged securely according to industrial safety regulations. We ensure quick dispatch and reliable goods transport, and customers can expect timely delivery across the Indian market.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Specaialty Equipments Category

2 Litre Reaction System with Instant Heating

Minimum Order Quantity : 1 Piece

Control System : Frequency Speed Control

Phase : Three Phase

Feature : High Efficiency

Material : Other, Stainless Steel

Voltage : 415 Volt (v)

Agitation,Mixing Equipment Systems

Minimum Order Quantity : 1 Piece

Control System : Human Machine Interface

Phase : Three Phase

Feature : High Efficiency

Material : Other, Stainless Steel

Voltage : 415 Volt (v)

25 Litre High Pressure Pilot Reactor for Polymer Industry

Minimum Order Quantity : 1 Piece

Control System : Human Machine Interface

Phase : Three Phase

Feature : High Efficiency

Material : Other, Stainless Steel

Voltage : 415 Volt (v)

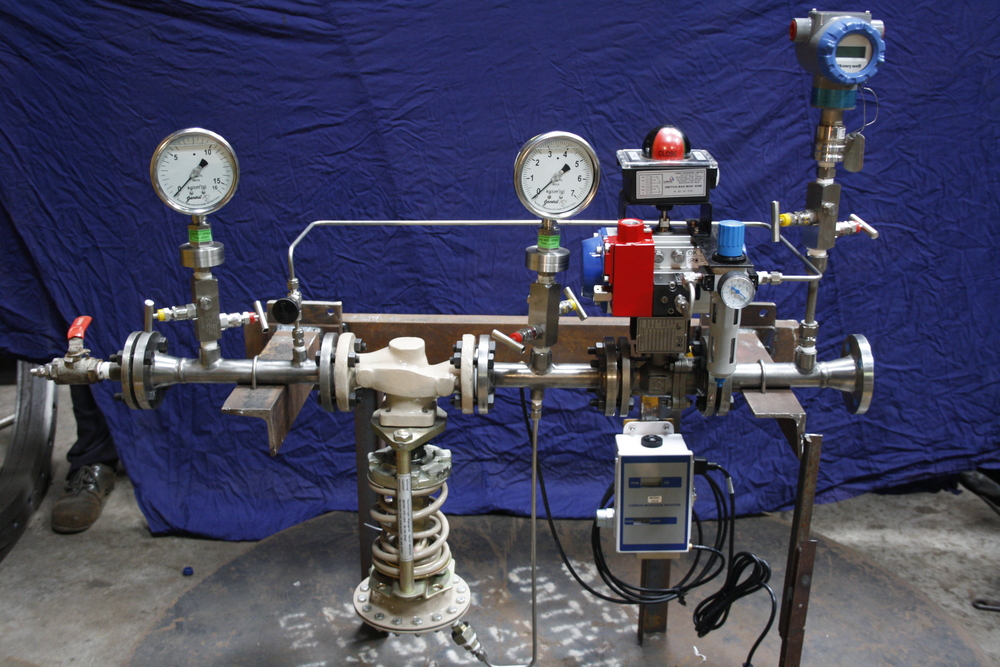

Pressure Reducing Stations

Minimum Order Quantity : 1 Piece

Control System : Human Machine Interface

Phase : Three Phase

Feature : High Efficiency

Material : Other, Stainless Steel

Voltage : 415 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese