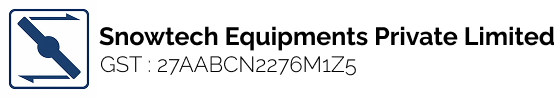

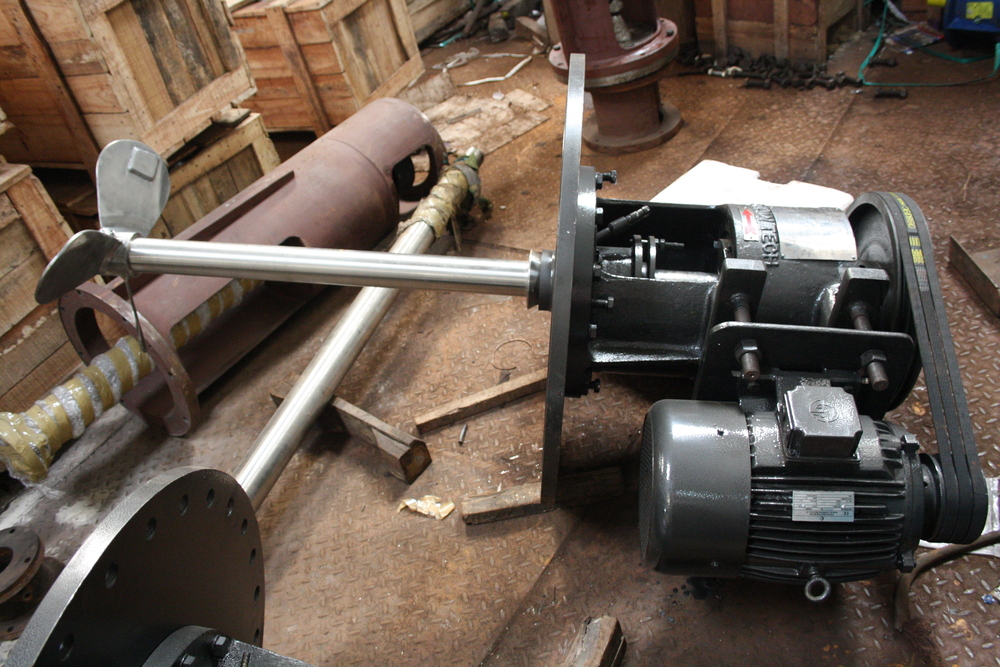

Agitator For High Viscosity Material Storage Tank

MOQ : 1 Piece

Agitator For High Viscosity Material Storage Tank Specification

- Condition

- New

- General Use

- Industrial

- Material

- Stainless Steel

- Drive Type

- Electric

- Voltage

- 220 Volt (v)

- Motor

- AC Motor

- Feature

- High Speed

- Warranty

- 1 Year

Agitator For High Viscosity Material Storage Tank Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 5-7 Days

- Main Domestic Market

- All India

About Agitator For High Viscosity Material Storage Tank

Capitalise on a gilt-edged opportunity with the Agitator For High Viscosity Material Storage Tank, available now for instant checkout. Driven by an electric AC motor and powered at 220 Volts, this agitator epitomises high-speed, monumental performance for industrial applications. Expertly crafted from stainless steel for durability and hygiene, it is perfect for demanding storage solutions. Jump on this glorious machine, backed by a 1-year warranty, whether you are a distributor, manufacturer, supplier, or trader in India seeking superior efficiency and reliability.

Versatile Industrial Agitator: Wide Range of Uses

The Agitator For High Viscosity Material Storage Tank is characterised by its robust application in diverse industrial scenarios. Designed for high viscosity substances, its Type Of Usage includes blending, mixing, and maintaining homogeneity in storage tanks. It is extensively used in sectors like chemicals, pharmaceuticals, and food processing, enhancing efficiency in any Use Type. Its adaptability ensures optimal results wherever viscous material handling is required.

Efficient Supply and Transport Solutions

Our agitators are ready for prompt transport services from the designated FOB Port, ensuring seamless delivery to your location. With a commendable supply ability, we quickly charge and dispatch orders to meet industrial demands across India's main domestic markets. Request an estimate to capitalise on worry-free logistics and reliable distribution, so your operations never lose momentum.

Versatile Industrial Agitator: Wide Range of Uses

The Agitator For High Viscosity Material Storage Tank is characterised by its robust application in diverse industrial scenarios. Designed for high viscosity substances, its Type Of Usage includes blending, mixing, and maintaining homogeneity in storage tanks. It is extensively used in sectors like chemicals, pharmaceuticals, and food processing, enhancing efficiency in any Use Type. Its adaptability ensures optimal results wherever viscous material handling is required.

Efficient Supply and Transport Solutions

Our agitators are ready for prompt transport services from the designated FOB Port, ensuring seamless delivery to your location. With a commendable supply ability, we quickly charge and dispatch orders to meet industrial demands across India's main domestic markets. Request an estimate to capitalise on worry-free logistics and reliable distribution, so your operations never lose momentum.

FAQ's of Agitator For High Viscosity Material Storage Tank:

Q: How does the agitator benefit storage of high viscosity materials?

A: The agitator efficiently blends and maintains uniform consistency in storage tanks, preventing sedimentation and ensuring optimal quality of high viscosity materials in industrial applications.Q: What is the process for installing the agitator in a storage tank?

A: Installation is straightforward: the agitator is mounted in the designated tank opening, connected to electrical supply, and tested for high-speed performance, making it ready for immediate use.Q: When should maintenance be scheduled for this agitator?

A: Routine maintenance is recommended every six months or as per operational intensity to ensure smooth performance and longevity of both the electric motor and stainless steel components.Q: Where can the agitator be used effectively?

A: This agitator is particularly effective in industries such as chemicals, food processing, and pharmaceuticals-anywhere high viscosity materials require robust mixing and storage.Q: What is the warranty period and coverage for the agitator?

A: The product comes with a 1-year warranty covering manufacturing defects and motor malfunction, ensuring peace of mind and reliable operational support for your business.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Agitators And Mixers Category

Multi Impeller Agitator

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Condition : New

Drive Type : Electric

Voltage : 220 Volt (v)

Feature : High Speed

Side Entry Agitator

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Condition : New

Drive Type : Electric

Voltage : 220 Volt (v)

Feature : High Speed

Multiple Impeller Agitator With Foam Breaker

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Condition : New

Drive Type : Electric

Voltage : 220 Volt (v)

Feature : High Speed

Agiatator For Bitumen Emulsion Service

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Condition : New

Drive Type : Electric

Voltage : 220 Volt (v)

Feature : High Speed

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese