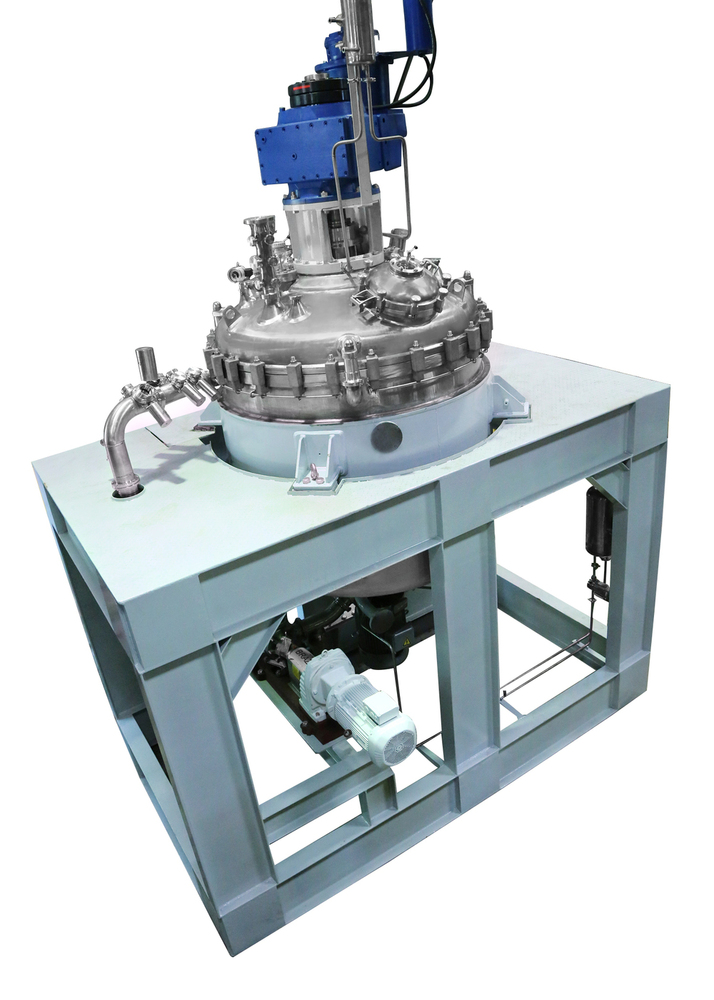

Batch Emulsion Preparation Pilot System For Cosmetic Industry

Batch Emulsion Preparation Pilot System For Cosmetic Industry Specification

- Phase

- Three Phase

- General Use

- Industrial

- Material

- Stainless Steel

- Automatic

- Yes

- Control System

- Frequency Speed Control

- Surface Treatment

- Polishing

- Voltage

- 415 Volt (v)

- Feature

- High Efficiency

- Warranty

- 1 Year

Batch Emulsion Preparation Pilot System For Cosmetic Industry Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 5-7 Days

- Main Domestic Market

- All India

About Batch Emulsion Preparation Pilot System For Cosmetic Industry

Versatile Usage and Superior Features

This Batch Emulsion Preparation Pilot System is tailored to meet the dynamic requirements of the cosmetic industry, excelling in pilot-scale production, formulation testing, and process development. The system stands out with automatic operation, frequency speed control, and superior safety mechanisms. Premium stainless steel construction ensures durability while the polished surface offers enhanced hygiene. Ideal for both R&D labs and scaled-down manufacturing, it provides operational flexibility for industry professionals seeking reliability.

Sample Access, Domestic Reach, and Delivery Details

Handover of system samples is available for industrial customers, allowing hands-on demonstrations prior to expenditure. This rare, top-tier unit is offered across India's main domestic markets, ensuring extensive distribution coverage. Packaging is managed meticulously, with robust materials safeguarding the system during drop-off to the client's site. We prioritize transparency, ensuring smooth coordination from order to delivery, minimizing risks and additional costs associated with shipping and installation.

FAQ's of Batch Emulsion Preparation Pilot System For Cosmetic Industry:

Q: How does the automatic control system enhance the operation of the pilot system?

A: The automatic control system streamlines operation by regulating frequency speed and ensuring precise mixing, which improves consistency and overall process efficiency in batch emulsion preparation.Q: What is the benefit of using stainless steel with polished surface treatment?

A: Stainless steel with a polished finish provides superior durability, excellent resistance to corrosion, and enhanced hygiene-ideal for cosmetic applications demanding uncompromised product quality.Q: Where is the Batch Emulsion Preparation Pilot System distributed in India?

A: The system is supplied across India's main domestic markets by a network of trusted manufacturers, distributors, and suppliers to ensure wide accessibility.Q: What features make this pilot system suitable for the cosmetic industry?

A: Key features such as high efficiency, frequency speed control, automatic operation, and durable construction make it ideal for handling delicate formulations required by cosmetic manufacturers.Q: What kind of packaging and delivery can clients expect upon purchase?

A: Clients receive the system in robust, secure packaging designed to prevent transit damage; delivery is coordinated with precise drop-off and handover processes at the client's location.Q: How can manufacturers test the system before completing their expenditure?

A: Sample handover is available for testing, allowing clients to assess functionality and performance before making purchasing commitments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mixing System Category

Emulsion Vessel With Hydraulic Lid Lifting

Minimum Order Quantity : 1 Piece

Surface Treatment : Polishing

Control System : Frequency Speed Control

Feature : Simple Control

Phase : Three Phase

General Use : Industrial

Contra Rotating High Shear Mixing System With Pneumatic Lifting System For Pharma Industry

Minimum Order Quantity : 1 Piece

Surface Treatment : Polishing

Control System : Frequency Speed Control

Feature : High Efficiency

Phase : Three Phase

General Use : Industrial

Batch Emulsion Preparation System For Cosmetic Industry

Minimum Order Quantity : 1 Piece

Surface Treatment : Polishing

Control System : Frequency Speed Control

Feature : High Efficiency

Phase : Three Phase

General Use : Industrial

High Speed Mixer With Lid Pnuematic Lid Lifting For Emulsion Service

Minimum Order Quantity : 1 Piece

Surface Treatment : Polishing

Control System : Frequency Speed Control

Feature : High Efficiency

Phase : Three Phase

General Use : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese