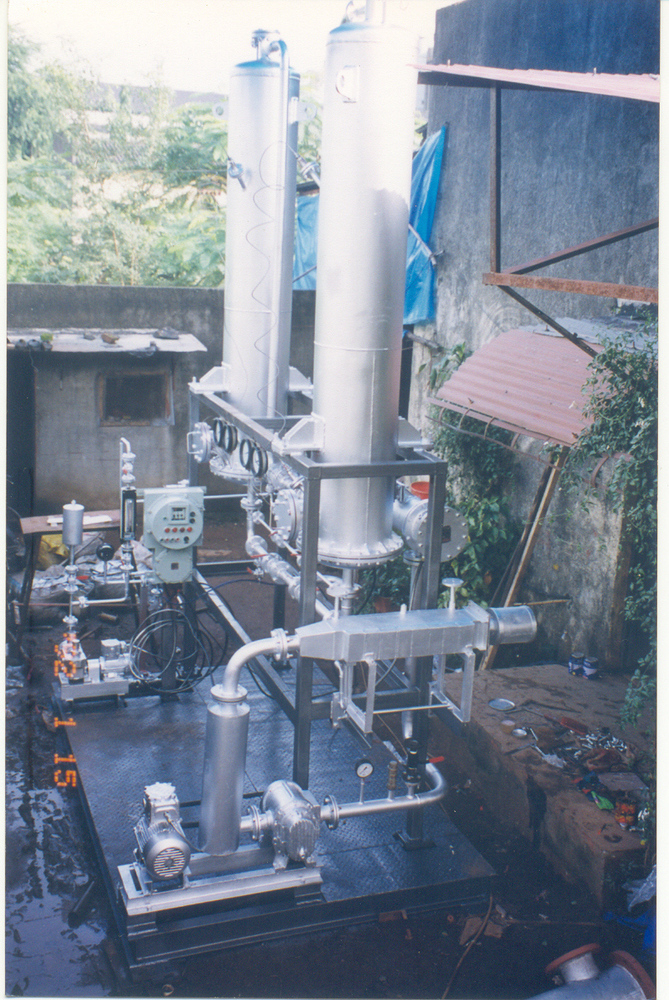

Distillation Skid For Bio Diesel Manufacturing Facility

Distillation Skid For Bio Diesel Manufacturing Facility Specification

- Material

- Stainless Steel

- Automatic Grade

- Automatic

- Voltage

- 415 Volt (v)

- Frequency (MHz)

- 50 Hertz (HZ)

- Size

- Customized

- Warranty

- 1 Year

Distillation Skid For Bio Diesel Manufacturing Facility Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 5-7 Days

- Main Domestic Market

- All India

About Distillation Skid For Bio Diesel Manufacturing Facility

Extensive Applications in Bio Diesel Manufacturing

Our Distillation Skid for Bio Diesel Manufacturing Facility is expertly designed for versatile deployment. Ideal for large-scale bio diesel production plants, it enhances multiple application areas, including industrial fuel processing, energy plants, and sustainable fuel development. Used for the critical separation and purification of bio diesel, this machinery elevates operational efficiency, and is suitable for plants seeking dependable, continuous automatic processing capabilities. Invest in superior plant application and secure optimal output for your facility.

Robust Supply Ability and Expansive Export Market Reach

With a strong supply ability, our proposal amount can be adjusted to suit your bulk requirements. We primarily serve the international export market, making our distillation skids a popular choice among global buyers seeking market value solutions. Sample availability ensures confidence in our product quality before full-scale orders. By consistently supporting large and small scale ventures alike, we cater to diverse market needs and maximize your plant's value in the competitive renewable energy sector.

FAQ's of Distillation Skid For Bio Diesel Manufacturing Facility:

Q: How does the automatic grade feature benefit bio diesel manufacturers?

A: The automatic grade functionality streamlines the distillation process, reducing manual intervention and increasing consistency. This leads to greater operational efficiency, minimizes human errors, and ensures a uniform high-quality biodiesel output, making the manufacturing process more reliable and cost-effective.Q: What process does the Distillation Skid follow during biodiesel production?

A: The Distillation Skid separates and purifies biodiesel from other substances, utilizing precise temperature and pressure controls. Automated controls maintain optimal performance, ensuring impurities are efficiently removed and only high-grade biodiesel is collected for use or further processing.Q: When should a bio diesel facility consider upgrading to a masterful distillation skid?

A: Facilities should consider upgrading when scaling up production, seeking higher efficiency, or aiming for improved purity in their biodiesel. A modern automatic skid delivers better quality control and supports growth by handling increased volumes with ease.Q: Where can these distillation skids be installed?

A: Our customized distillation skids are designed for flexible installation in various biodiesel production facilities, including industrial plants, energy parks, and dedicated renewable resource centers. Their robust construction allows integration into both new and existing plant infrastructures across India and export markets.Q: What warranty and support are offered with the unit?

A: Each Distillation Skid comes with a 1-year warranty covering manufacturing defects and operational issues. Our support team assists clients throughout installation, commissioning, and maintenance, providing peace of mind and ensuring seamless operation.Q: How does the supply process work, and is a sample available?

A: We provide a tailored proposal amount based on your requirements and supply ability. Prospective buyers can request sample units to evaluate our skid's performance and build quality before committing to larger orders, ensuring satisfaction and transparency throughout the supply process.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Distilation And Separation System Category

Skid Of Mol. Sieve Based Solvent Drying System

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Frequency (MHz) : 50 Hertz (HZ)

Voltage : 415 Volt (v)

Automatic Grade : Automatic

Material : Stainless Steel

Batch Vaccum Distillation Pilot Plant

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Frequency (MHz) : 50 Hertz (HZ)

Voltage : 415 Volt (v)

Automatic Grade : Automatic

Material : Stainless Steel

Reboiler Of Batch Distillation Unit

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Frequency (MHz) : 50 Hertz (HZ)

Voltage : 415 Volt (v)

Automatic Grade : Automatic

Material : Stainless Steel

Distillation Skid For Bio Diesel Manufacturing Facility

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Frequency (MHz) : 50 Hertz (HZ)

Voltage : 415 Volt (v)

Automatic Grade : Automatic

Material : Stainless Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese