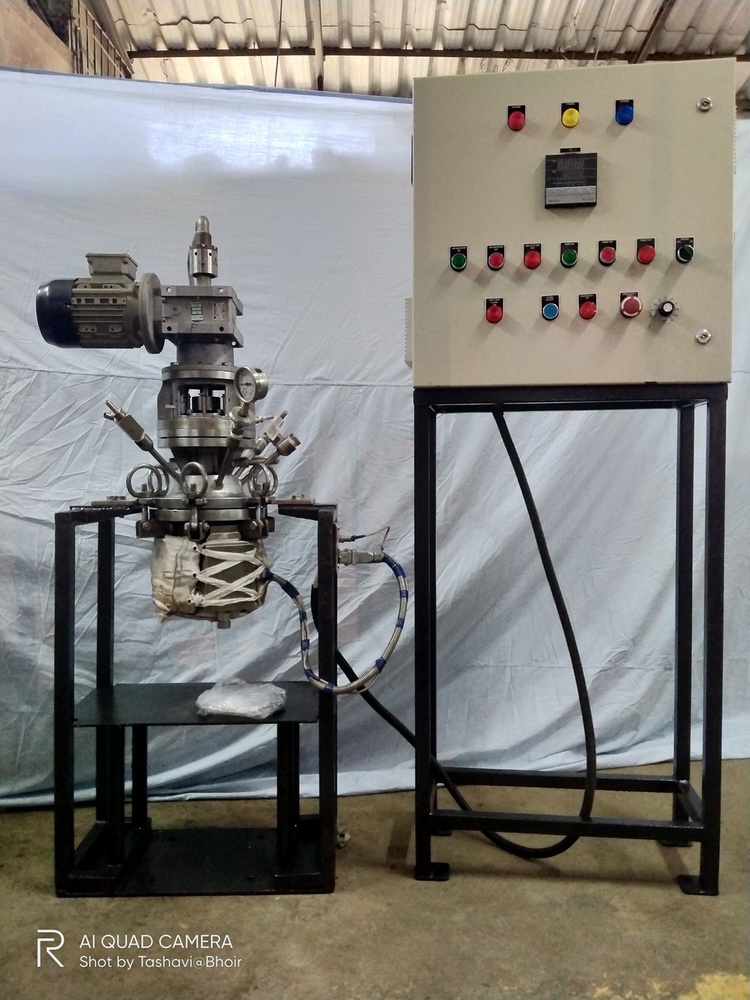

Kilo Lab Batch Reactor Skids For Pharma

MOQ : 1 Piece

Kilo Lab Batch Reactor Skids For Pharma Specification

- Phase

- Three Phase

- General Use

- Industrial

- Material

- Stainless Steel

- Automatic

- Yes

- Control System

- Frequency Speed Control

- Surface Treatment

- Polishing

- Voltage

- 415 Volt (v)

- Feature

- Simple Control

- Warranty

- 1 Year

Kilo Lab Batch Reactor Skids For Pharma Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 5-7 Days

- Main Domestic Market

- All India

About Kilo Lab Batch Reactor Skids For Pharma

Jump on pivotal innovation with our Kilo Lab Batch Reactor Skids for Pharma, engineered for supreme performance in industrial applications. Crafted from valorous stainless steel and enhanced with a polishing surface treatment, these reactor skids promise automatic operation and simple control. The frequency speed control system ensures process precision, while the 415 Volt, three-phase compatibility guarantees robust power. Available across India, buy online or contact our team-distributor, manufacturer, supplier, and trader-for supreme outlay markdown and stellar after-sales support, including a 1-year warranty.

Exceptional Features and Practical Applications

Kilo Lab Batch Reactor Skids for Pharma are designed for laboratory and industrial site applications. These skids feature simple yet effective control systems, including frequency speed control, facilitating reliable and accurate processing. Constructed from durable stainless steel and finished with polishing, their usage type is automatic, ensuring operational efficiency for pharmaceutical manufacturers. Ideal for scale-up studies and pilot production, these machines provide pivotal support in pharmaceutical R&D and batch production.

Reliable Supply, Secure Packaging, and Market Coverage

Estimate your production needs with confidence-our Kilo Lab Batch Reactor Skids are available for prompt dispatch across India, ensuring minimal delivery outlay. Packaging details emphasize secure, damage-resistant solutions for every batch skid. The primary domestic market is India, serviced through an efficient distributor and supply network, optimizing both reach and response time. Rely on us for a seamless purchasing experience and dependable after-sales support for your batch reactor requirements.

Exceptional Features and Practical Applications

Kilo Lab Batch Reactor Skids for Pharma are designed for laboratory and industrial site applications. These skids feature simple yet effective control systems, including frequency speed control, facilitating reliable and accurate processing. Constructed from durable stainless steel and finished with polishing, their usage type is automatic, ensuring operational efficiency for pharmaceutical manufacturers. Ideal for scale-up studies and pilot production, these machines provide pivotal support in pharmaceutical R&D and batch production.

Reliable Supply, Secure Packaging, and Market Coverage

Estimate your production needs with confidence-our Kilo Lab Batch Reactor Skids are available for prompt dispatch across India, ensuring minimal delivery outlay. Packaging details emphasize secure, damage-resistant solutions for every batch skid. The primary domestic market is India, serviced through an efficient distributor and supply network, optimizing both reach and response time. Rely on us for a seamless purchasing experience and dependable after-sales support for your batch reactor requirements.

FAQ's of Kilo Lab Batch Reactor Skids For Pharma:

Q: How does the frequency speed control system enhance operation of the Kilo Lab Batch Reactor Skids?

A: The frequency speed control system allows precise adjustment of agitation speeds, ensuring optimal mixing and reaction conditions. This feature helps maintain consistency, quality, and flexibility during pharmaceutical batch processes.Q: What materials are used in the construction of these batch reactor skids?

A: Our batch reactor skids are manufactured from high-grade stainless steel with a polished finish, providing both durability and corrosion resistance essential for pharmaceutical environments.Q: When can I expect my batch reactor skids to be dispatched after purchase?

A: Dispatched promptly once your order is confirmed, lead times vary depending on order size and location. You will receive an estimated dispatch date upon purchase to help with production planning.Q: Where are these reactor skids most commonly applied?

A: They are primarily used in pharmaceutical research labs, pilot plants, and industrial manufacturing facilities, particularly for process development and batch production in India.Q: What are the main benefits of using an automatic batch reactor with simple control features?

A: Automatic operation combined with simple controls streamlines processing, enhances safety, minimizes operator intervention, and boosts overall productivity for pharmaceutical batch manufacturing.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Turnkey Customized Skid Mounted Pilot Plant Category

Multi Reactor Pilot Plant Skid

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Voltage : 415 Volt (v)

Phase : Three Phase

General Use : Industrial

Feature : High Efficiency

Batch Pilot Reactor Skid In Hastealloy For Pharma Industry

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Voltage : 415 Volt (v)

Phase : Three Phase

General Use : Industrial

Feature : High Efficiency

Pilot Reactor For Polymer Service

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Voltage : 415 Volt (v)

Phase : Three Phase

General Use : Industrial

Feature : High Efficiency

High Temperature Pyrolysis Reactor Pilot Plant

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Voltage : 415 Volt (v)

Phase : Three Phase

General Use : Industrial

Feature : Simple Control

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese